gordon

Total Posts: 31

Joined: June 24, 2013

|

We're building a pair of twin 22" mirrors for a binocular telescope!

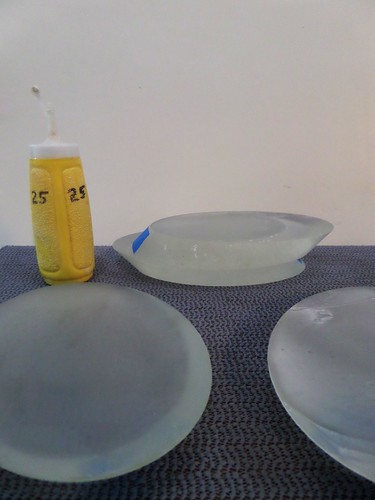

I believe that these 22" bino's are likely to be the largest pair of binoculars in amateur hands. The first thing to arrive was a box of small glass from Newport. In addition to the two primary mirrors, we are also fabricating the flat elliptical secondary mirrors. This first shipment of glass contains four elliptical blanks, all with 5.5" minor axis measurements.

As always, the glass was well-packed and arrived in good time from the glass fab.

Tags:

Posted on December 27, 2013 at 3:33 PM

|

gordon

Total Posts: 31

Joined: June 24, 2013

|

Re: Starting work on the twin 5.5" elliptical secondary mirrors

Time to get to work on the 5.5" secondary blanks. The plan is to grind all eight sides of the four secondaries flat, then send two of them on the the client to be used as dummies during the fabrication of the instrument. The first step was to use a diamond hone to put a little bevel on all of the edges.

The blanks were Blanchard ground plano-plano at Newport, so I can start grinding with Microgrit 25-micron abrasive. With four flats and eight surfaces, I used a modification of the classic "three-mirror" procedure, grinding the mirrors top and bottom on each of the other mirrors.

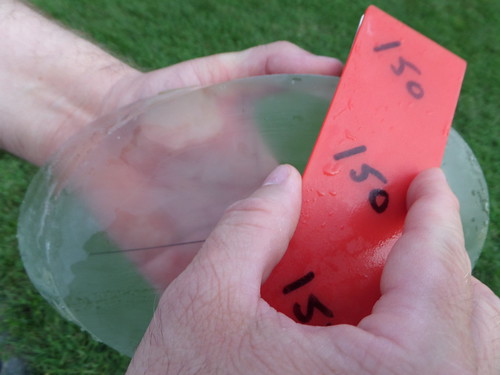

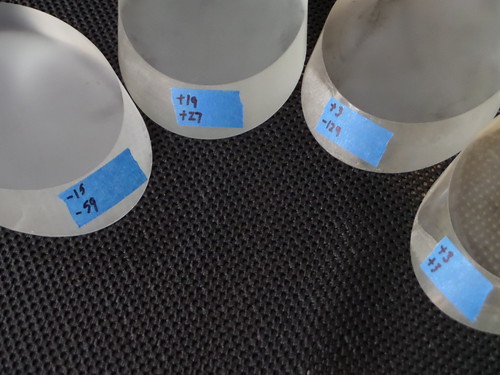

The flats are tested on my Strasbaugh computer-controlled spherometer, using a 5" diameter test probe. As each face is measured, I write the deviation from flat -- in 1/100,000ths of an inch -- on a piece of tape on each mirror,

As the deviations fall, I match pairs of faces to improve each surface. So convex is ground against convex, and concave against concave. As grinding progresses and the mirrors become flatter, I move from 25-micron down to 12-micron Microgrit, and finally finish at 9-micron. When the deviations are .00003 inches or less, I consider this stage of fabrication to be complete.

Posted on December 27, 2013 at 3:34 PM

|